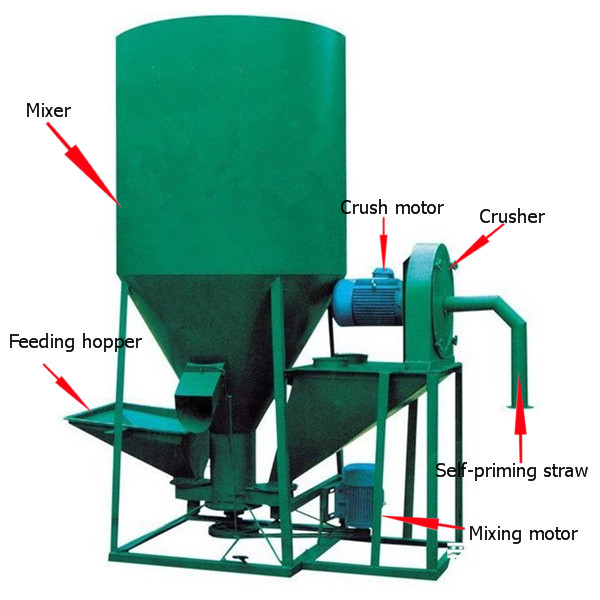

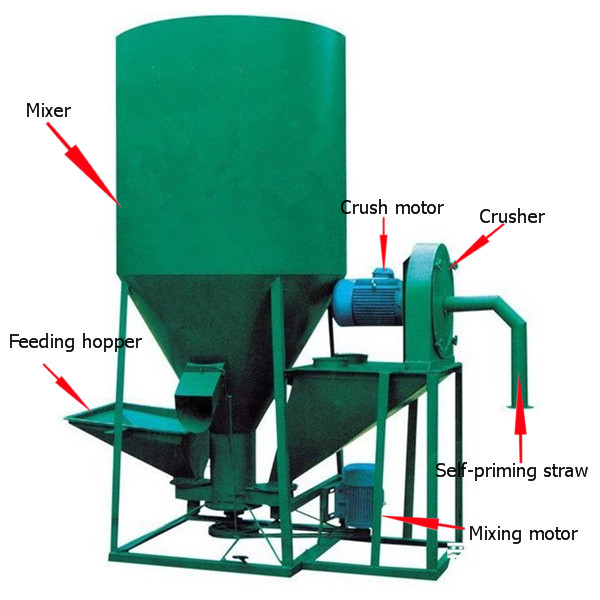

Features

Feed crusher applies to professional processing households and large, medium or small farms feed processing. This machine combines crushing, mixing, the blowing of air, sprinkling and other such functions in one body. It has an advanced design, durable structure, reliable performance, convenient maintenance, high efficiency, occupies little space, energy and time efficient, produces little dust and is well sealed for storage of the feed. It is the best choice for animal feeding.

Working Principle

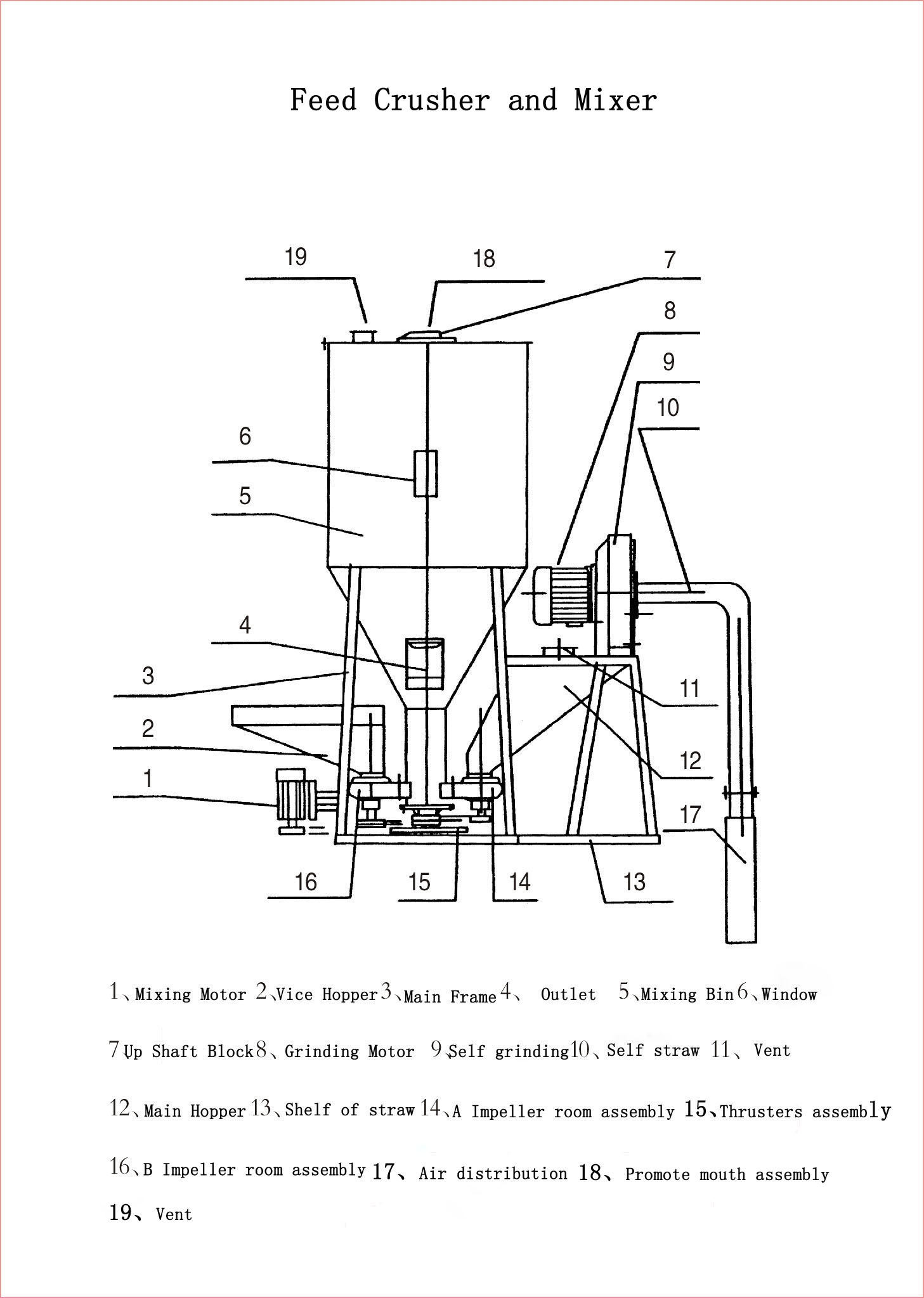

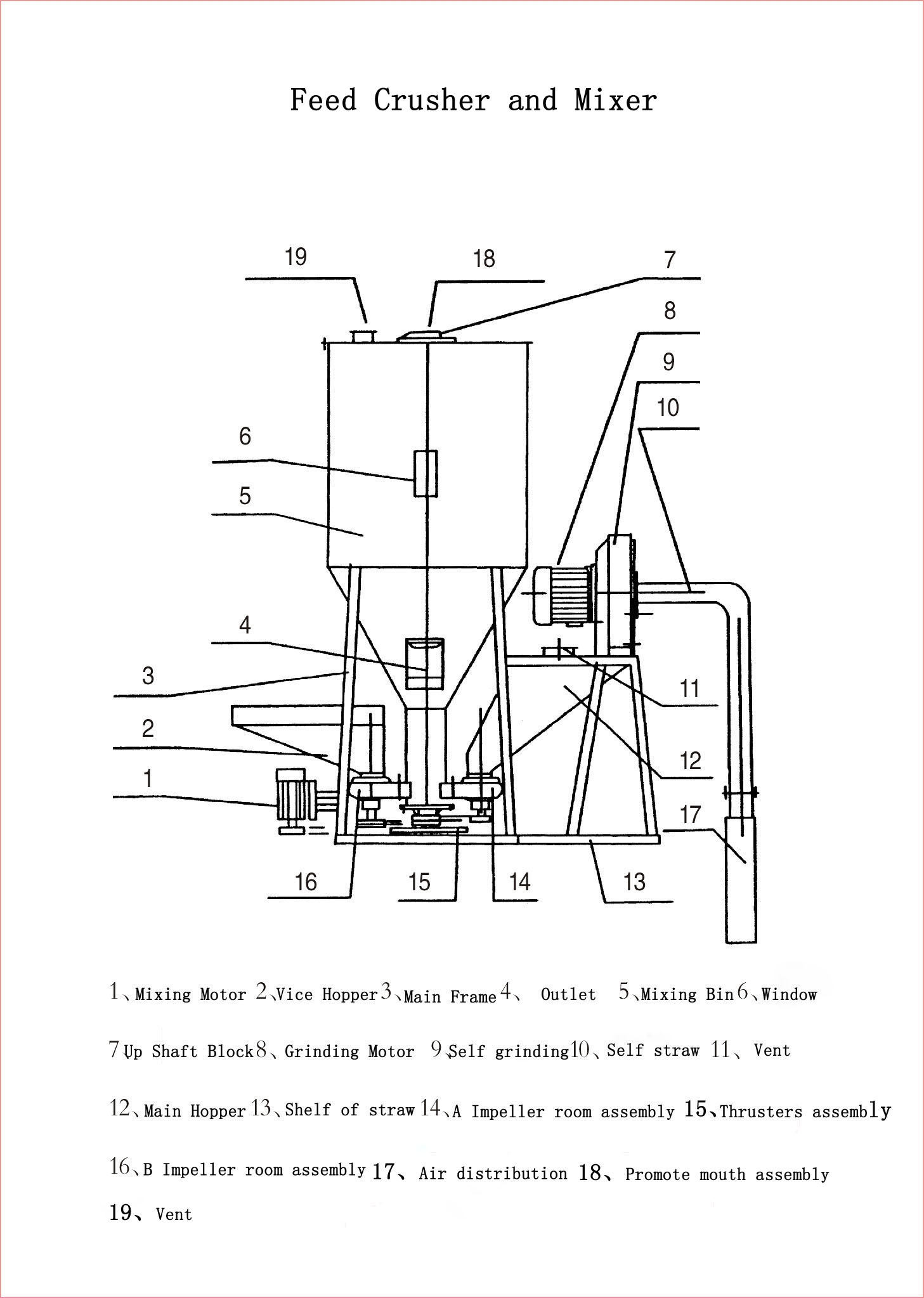

This series of feed crushing mixer has two main components, crushing components and mixing components.

1.The crushing mechanism: Automatic feeding or manual feeding. When the materials are inhaled or sent into the crushing chamber, the feed is beaten and crushed continuously by the rotor blades, then shattered into powder or pellet immediately. By the force of centrifuge and airflow, the materials get into the impelling box through A screen hole and then to the transporting pipe.

2.Mixing components: When the material propeller rotates, the materials are forcibly sent through the room B impeller to transporting pipe and ascended to the top of the silo. Just like this, the materials keep going up and down as well as rotating, the mixing process is formed. The mechanism determines the fine efficiency of the mixing components.

Installation & Adjustment

1.Before installation, refer to the instruction book and then install according to the provisions set out in the book.

2. Regulate and set the machine, ensuring the necessary speed and stable rotation.

3.380 v power supply. Switch, insulated wire should be reliable and convenient to control. Applying current which is greater than the motor rated current should not be attempted. The electric equipment must be grounded.

4.Check all the connected parts to see whether the bolts are loose. Manually push shaft to check whether they have stuck or collided, and whether they are still flexible. Also check if the hammer is reliable and flexible.

5.The motor rotation should rotate according to the direction specified according to the arrow on the sign. If not, it will not work, but you can exchange any two wire joint positions of the motor to make it work.

6.Check the tightness of the triangle belt to make it properly fit.

7.Check input feeding pipe, and other connected components of the mixing machine, making sure that there is no powder leakage at each part. No leakage means everything is normal.

8.The workplace should be spacious and well ventilated as well as equipped with fire prevention measures.